REALIZING THE ENVIRONMENTAL PROTECTION OBJECTIVES

We are convinced that the continuous development of our activities in the field of environmental protection is a decisive condition for the fulfillment of customer demands as well as the seamless operation and growth of our company. Therefore, all processes and activities of our company have been rationalized in line with the ISO 14001 environmental standards. In 2010, we decided to drastically reduce the amount of hazardous waste byproducts generated during the manufacturing process:

- soiled cylinder washing liquid is regenerated;

- machines are cleaned with high quality reusable wipes cleaned and replaced by the supplier upon demand;

- waste oil generated during equipment maintenance is removed and recycled by the maintenance company;

- non-hazardous waste has always been collected separately and treated;

- in 2010, we started collecting PET bottles on the premises of the printing house.

PROCUREMENT AND USE OF MATERIALS

We continuously strive to meet the most demanding expectations when it comes to materials used in the production process, such as paper, ink or varnish, in terms of both quality and environmental protection.

PEFC STANDARD

In 2014, the leadership decided to embrace an environmentally sound paper management. After a lengthy auditing process which spanned several days and involved thorough investigation in line with the strict regulation, we were awarded the PEFC certification in January 2015. What do PEFC standards cover and what is the PEFC methodology? PEFC (Program for the Endorsement of Forest Certification) is a system of forestry certification and product monitoring system which allows clients to distinguish between wood-based products which were produced according to sustainability requirements from those products which were not. Awarded with the condition that PEFC standard requirements are fulfilled, the certification ensures the traceability of products from the forest through wood-based products until the consumer, thus excluding the use of illegally acquired materials. All actors of the production chain can be certified in accordance with the appropriate PEFC standard for their activity. The certification and the logo ensures customers that sustainability regulations were observed during production. PEFC standards can be easily integrated with the ISO 14001 and OHSAS 18001 standards.

QUOTATION AND CALCULATION

As far as the nature and parameters of the products indended to be produced make it possible, we offer in any case FSC<sup style=”font-size: 14px;”>>®</sup> certified base materials as well as environmentally friendly ink and varnish to our customers.

CTP PLATE MAKING TECHNOLOGY

In the spirit of environmental awareness, we replaced the previous Viola system with Thermal CTP technology in 2008. As a result, energy consumption and waste generation dropped by 30-40%. Considered hazardous waste, used developer liquid was entrusted to a company which offers to recycle it into engine cleaner liquid with the use of additives.

PRINTING

Reduction of the amount of isopropyl alcohol used in production was greatly facilitated by our project initiated in 2010 and realized within 2 years which provided for the purchase of four cutting-edge printing units. After the new units were deployed, the amount of isopropyl alcohol used dropped to values between 3 and 8%. In 2010, as part of a CHOP tender for the development of environment-friendly technology, a Heidelberg XL -75-8-P type printing press was put into operation. The targets set out in the tender were duly met: the amount of isopropyl alcohol was reduced by 56% and overall emission was reduced by 90%. This fact was certified by SGS Hungária Ltd. and a verification report was issued to our company. The investigation period was between 1 April 2010 and 6 July 2010. The company went on to upgrade three more printing units to BAT technology.

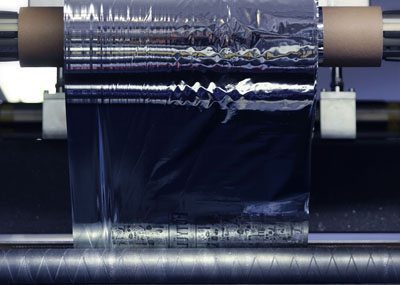

Packaging

Kraft paper and stretchfoil is used for packaging finished products. Thanks to the investment made in 2009, we were able to replace the initially applied manual wrapper and upgrade to a pallet wrapping machine with special pre-stretching function which reduces the required amount of plastic foil by 20-30%.

MANAGEMENT OF WASTE PRODUCED BY DIE CUTTING AND THE OPERATION OF EUROBIND 4000 ADHESIVE BINDER

During the building expansion project concluded in 2011, we deployed a special conveyor belt system under the die cutting machine to collect waste matter which is forwarded into an automatic hopper compactor and then into the central paper waste collector of the plant. Turnings generated during milling operations of the adhesive binder put into operation in December 2012 is collected with an extractor fan into special canvas bags which are emptied into paper waste collection containers. Conveyor discharge channels were built downstream of all three bladed cutter sections of the machine to ensure that turnings are forwarded directly into the container.

DEVELOPMENT OF THE IMMEDIATE ENVIRONMENT OF KESKENY PRINTING HOUSE

In the fall of 2012 and the spring of 2013, we carried out significant landscape development in the post-production stage of the previous year’s construction activities. As part of this, we planted ten sour cherry trees, four walnut trees, three apple trees, four hazelnut shrubs and one date palm. We planted grass over a surface of 3,000 m² to increase the green area. In the fall of 2012, we constructed a 16-stand indoor bike storage facility in order to promote environmentally conscious means of transport among our employees, hoping to reduce the number of car users.

LAUNCHING A HIKING DEPARTMENT

In 2013, we launched our hiker program with the intention to encourage the environmentally conscious behavior among our employees. Personal experiences gained during hiking may facilitate the awareness of our responsibility for protecting natural assets and thus promote a more environmentally friendly treatment of our immediate surroundings, whether at work or at home. Tour dates and locations have been purposely selected by the tour guide in such a fashion as to win over the most possible people to the case. Annual tour schedules are indicated on four notice boards for all employees to see. Separate invitations are prepared for each hiking tour, including an application form. After the tours, photomontage posters are posted to help remember the most memorable moments.

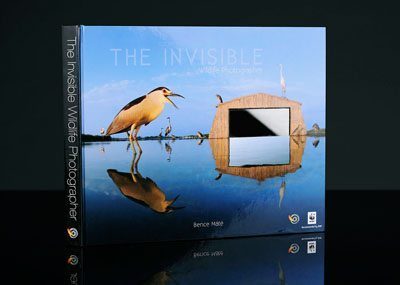

ACTIVE SUPPORT FOR ENVIRONMENTAL PROTECTION

In June 2013, Keskeny Printing House joined the international environmental protection organization WORLD LAND TRUST (WLT) as a supporter. WLT is a nonprofit organization funded by donations which actively intervenes worldwide using direct measures to ensure the survival of rain forests and endangered species. We would like to draw the attention of our partners that they have the chance to support WLT through our printing house, by ordering products with the WLT logo. A part of the sales price of such printed products is transferred to the organization, in support of their activity.