Get a special surface treatment for your prints and grab the attention of your customers! The digital 3D UV technology blends the most exciting conventional finishing processes, produced by one single machine. All you need to do is to select the procedure you prefer to make your publication or packaging more special and we will prepare it with pinpoint precision with the help of our digital coating machine.

OPPORTUNITIES AND BENEFITS

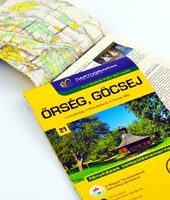

1.) 3D UV coating with low layer thickness (”smooth”)

Glossy varnish surface on the print, on smaller graphic design elements or larger areas.

- It’s more cost-effective than the conventional procedure if the coverage ratio of the surface to be varnished is low;

- no need to make a screen;

- the digital 3D UV technology uses extra glossy varnish, which results in an even more spectacular effect;

- no need to involve subcontractors, we can produce everything locally while constantly monitoring the entire manufacturing process;

- the digital technology does not require high quantities of sheets for set up.

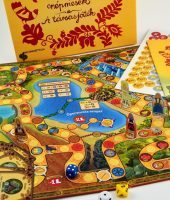

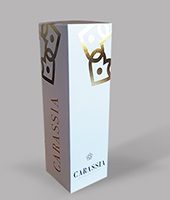

2.) 3D UV

Varnish layers with variable thickness, cambered on the graphic design elements.

- Variable varnish thickness: we can provide varnish layer thickness from 7 to 232 microns;

- even if you need 3D UV coating on a thin line or an extended area, the varnish will spread neatly and perfectly on the surface.

- pinpoint accuracy: Thanks to the technology, the varnish exactly fits the provided graphic design elements, there is no drift or any other inaccuracy,

- it can even replace embossing, too. There is no cliché cost: unlike in the conventional embossing process, the paper surface remains flat with only the UV coating being cambered, so you don’t need to worry about keeping the graphic design elements away from the cambered surface on the back side of the product: you can fully utilize the entire surface of the paper;

- you can develop varnish layers with different heights within 1 graphic design.

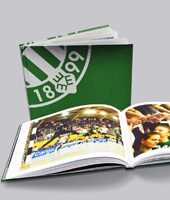

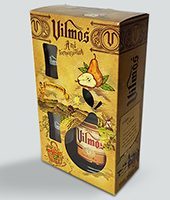

3.) 3D UV + hot foil stamping

Glossy golden or silver cambered surfaces

- No matter if it’s a very thin line or a larger extended area, we can apply hot foil stamping to any graphic design elements on the print;

- there’s no need for a cliché, which ensures significant cost saving, especially in the case of larger areas;

- the combination of hot foil stamping and 3D UV coating results in fine cambered surfaces with a minimum thickness of 29 microns;

- varnish height can be changed under the foil, so you can apply a combination of hot foil stamping and embossing to your product as well;

- the procedure results in a surface that is just as glossy and shiny as the product of the conventional hot foil stamping;

- the foil can be used more economically, the process is less waste-intensive, which is reflected in the price, too.

TEST OUR SKILLS AND GET A QUOTE TODAY!

If you have any more questions on the technology or the service, please contact us via the e-mail or mobile phone number below.

Contacts:

E-mail: info@keskenyprint.com

Phone: +36-1-414-3016

Leave a Reply