Sales Promotion for Product Packaging and Marketing Brochures: Cold Foil is Nearly Unbeatable!

Brand owners and marketers are always seeking innovative ways to make their products stand out from the competition. Whether it’s product packaging for pharmaceuticals or chocolates, conference materials, brochures, or book covers, the aim is to create something more beautiful, eye-catching, and exclusive than competitors. Achieving this without overspending is a bonus – and that’s where cold foil technology comes into play.

Though cold foil is not a new surface treatment technique, the market is just beginning to appreciate its potential. This technology can create a metallized surface similar to hot foil stamping, but with significant advantages: it’s easier, faster, more cost-effective, and more versatile.

Cold Foil Technology: Elegant Metallized Finishes Made Simple

One of the biggest advantages of cold foil is its ease of use. No special skills or software are required to create the artwork – it can be designed with standard graphic design software. All that’s needed is to include the graphic elements intended for cold foiling as a fifth color in the print file. Unlike hot foil stamping, cold foil can be applied to larger graphic areas as well as smaller details.

The process begins by applying glue to the paper, followed by pressing the foil onto the sheet. The foil can then be overprinted with ink to create a shiny, metallic effect. The color and saturation of the ink can further enhance this effect, allowing for either sleek, sophisticated designs or playful, bold ones.

Benefits of Cold Foil Technology

It’s often said that it’s what’s inside that counts, but when it comes to packaging, marketing brochures and covers, first impressions are critical. A study by the Foil & Specialty Effects Association (FSEA) found that packaging with a metallic finish attracts and retains customer attention 2.5 times faster than plain packaging. Cold foil technology offers a cost-effective way to achieve this, even for small print runs.

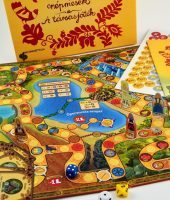

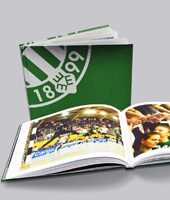

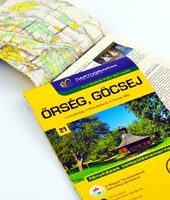

Versatile

Cold foil can be used on a wide variety of publications. It’s not limited to small graphics or thin lines, this technology works just as well on larger backgrounds and graphic elements. Additionally, cold foil allows for a broader color palette than hot foil stamping, enabling playful, bright designs while maintaining a luxurious appearance.

Cost-Effective & Fast

Most cold foil projects are printed inline, and since there’s no need to create clichés, the process is both cost-effective and faster than hot foil stamping. This results in excellent value for money, with quicker turnaround times even for smaller print runs.

By eliminating the need for second-pass printing and cliché production, unless additional surface treatments are required, you save both time and money while still achieving a premium, high-impact result.

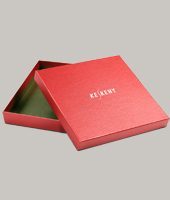

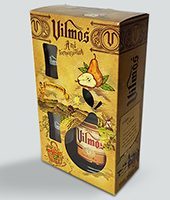

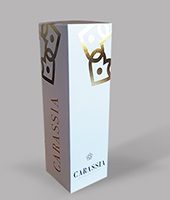

Variety of Applications

Cold foil has virtually unlimited applications, from decorative boxes and brochure covers to marketing materials that require a premium look. It’s an excellent choice for any print project that could benefit from a touch of metallic sparkle.

Whether it’s invitations, business cards, gift boxes, paper bags, high-profile covers, or packaging, cold foil delivers extraordinary results.

For more information, please contact us at marketing@keskeny.hu .