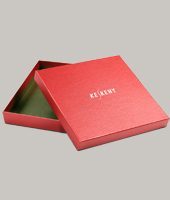

- We would like the packaging to imply that the box contains a unique product.

- We would like a unique and special premium packaging for our products, but it is very slow to order it from China, and the boxes are of a varying quality; from Western Europe it costs a fortune to procure unique rigid boxes.

These issues were often mentioned by our customers visiting Keskeny Printhouse, and they frequently expressed their demand for a resilient and exquisite mounted packaging with a unique design for their products.

Design was never an issue – our design department could design the ideal packaging –, but we could execute the mounting and the assembling of the rigid boxes only by involving suppliers. As a result of that, lead times were longer, and there were cases when the manufacturing of greater volumes caused a capacity problem.

Solution: Rigid box machine

Having recognized the above problems and needs, the printhouse decided to invest into a machine that would tackle these issues and enable the production of exquisite and resilient rigid boxes.

Installed at our printhouse at the beginning of this month, the rigid box machine has been tested under the supervision of our industrial designers, Márton Haraszti and László Borsos. Below is an interview with Márton Haraszti about his experiences with the machine and the products that can be manufactured with its help.

You have been testing the recently installed rigid box machine. What do we have to know about it?

M.H.: The machine is suitable for manufacturing different types of mounted products. We started producing the base and lid construction. According to our plans, we will be able to attain the production of 2,000 panels per hour. Other constructions will also be introduced in the near future (to be discussed in the next newsletters – the ed.)

How is a base and lid rigid box produced?

M.H.: During the manufacturing, the machine folds the partially cut grayboard into the desired form at one of the feeders. Meanwhile glue is applied onto the wrap (mounting) at another feeder. Then the grayboard and the wrap are adjusted onto each other with the help of a plunger, and finally glued together. That is how a mounted panel is produced.

What are the test results like?

M.H.: Our choice fell on this machine after a lengthy preliminary information gathering process. An important criterion was that it should provide as broad a variety of size and basic material as possible. The results are excellent. After fine-tuning the machine, we could achieve an extremely fine premium quality. What I mean by this is that the edges are beautiful, and the surfaces are very smooth even after gluing. End of March we started live production as well.

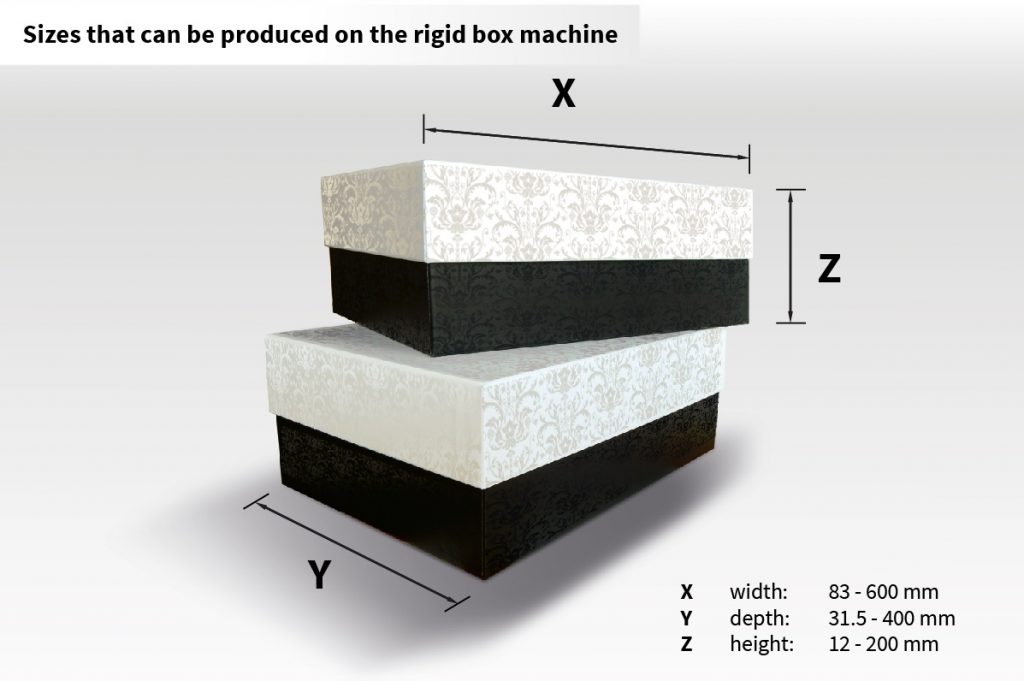

What sizes can be manufactured?

M.H.: Width: minimum 83 mm – maximum 600 mm, depth: minimum 31.5 mm –maximum 400 mm and height: minimum 12 mm – maximum 200 mm. So we will offer quite a broad range of sizes.

Click here to read about our standard sizes

And what about the choice of basic materials?

M.H.: The basic material is non-bending chipboard the thickness of which is selected depending on the size of the box. For smaller boxes, we recommend a 1–1.5 mm basic material, while for bigger sizes the ideal thickness is 2–3 mm. For the wrap, we can use traditional coated paper, but the elegance of the box can be enhanced by deploying materials produced especially for mounting.

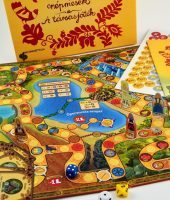

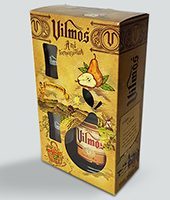

In what cases do you recommend the base and lid rigid box?

M.H.:When you want to place the goods in such packaging that will protect them from damages; or when it is important for the product to appear in a premium packaging because we want customers to feel that our product represents quality.

Typically, we recommend it for packaging beverages, chocolate, watches, perfume, technical appliances, clothes and accessories.

When can offers be requested for production on the new rigid box machine?

M.H.: Offers can already be requested since by the time we devise the ideal packaging for the product and the offer is approved by the customer, real production will begin on the machine.

More information: Csilla Dulai

Tel: +36 1 401 4076

E-mail: export@keskenyprint.com

Leave a Reply