PRODUCT-SPECIFIC TECHNOLOGICAL REQUIREMENTS

Product-specific technological requirements

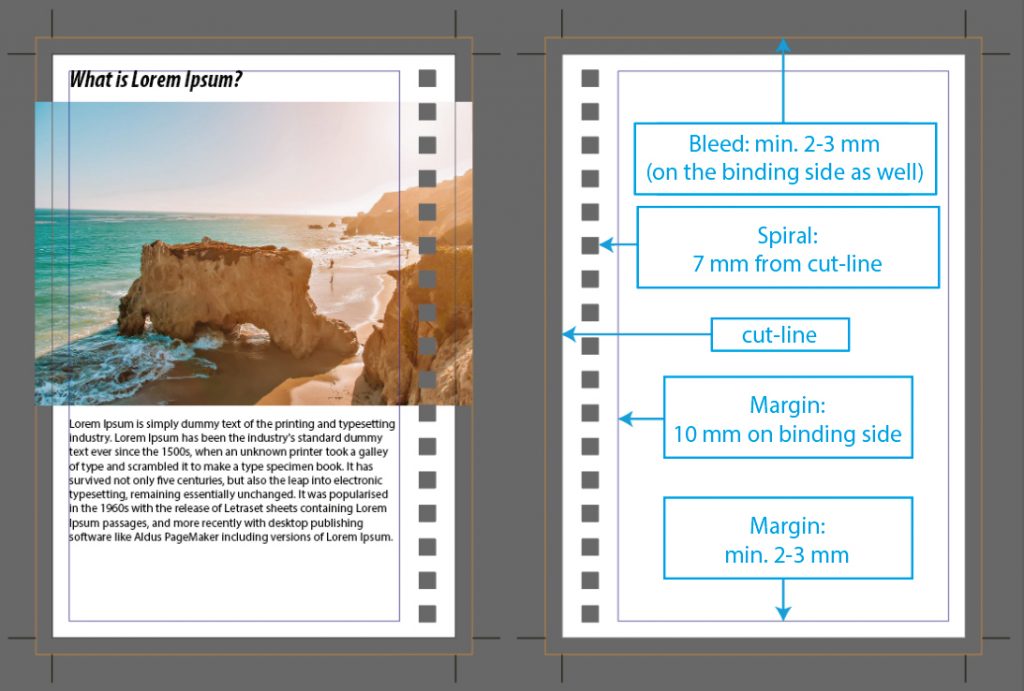

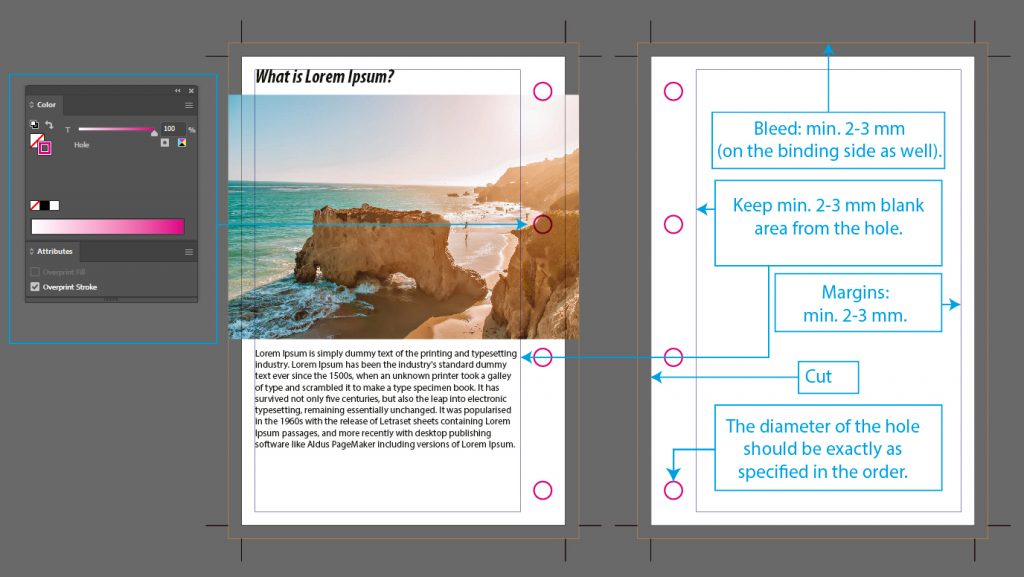

Spiral bound publications

For spiral bound publications, apply minimum of 3mm bleed on all four sides of the page.

On the binding side, non-bleeding graphic elements (texts, logo, etc.) should not be closer than 10mm to the cut-line, to leave a sufficient distance from the spiral punch.

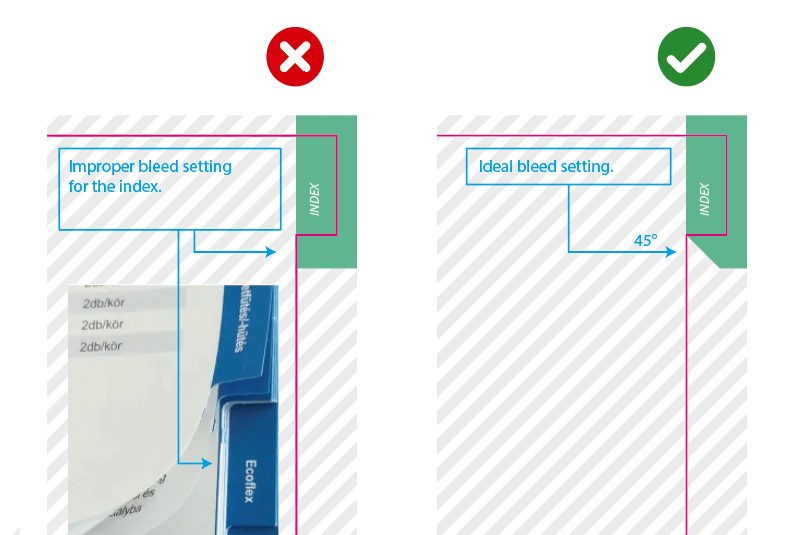

Indexed publications

Please mark the index cut-line with a vector line (stroke) colored with a spot color called “Index cut-line”, 100% tint, and overprint set to on.

If the index tab has a different color, it’s bleed should not run parallel to the edge of the sheet, but at 45°, as shown in the figures below.

Please mark the drilling with a separate spot color called “Hole”, 100% tint, overprint set to on and with a vector line (stroke). The diameter of the hole in the file must correspond to the size specified in the order (if necessary, please consult with our contact person). For safe production, it is necessary to leave a minimum distance of 2-3 mm from the edge of the hole for texts, logos, etc.

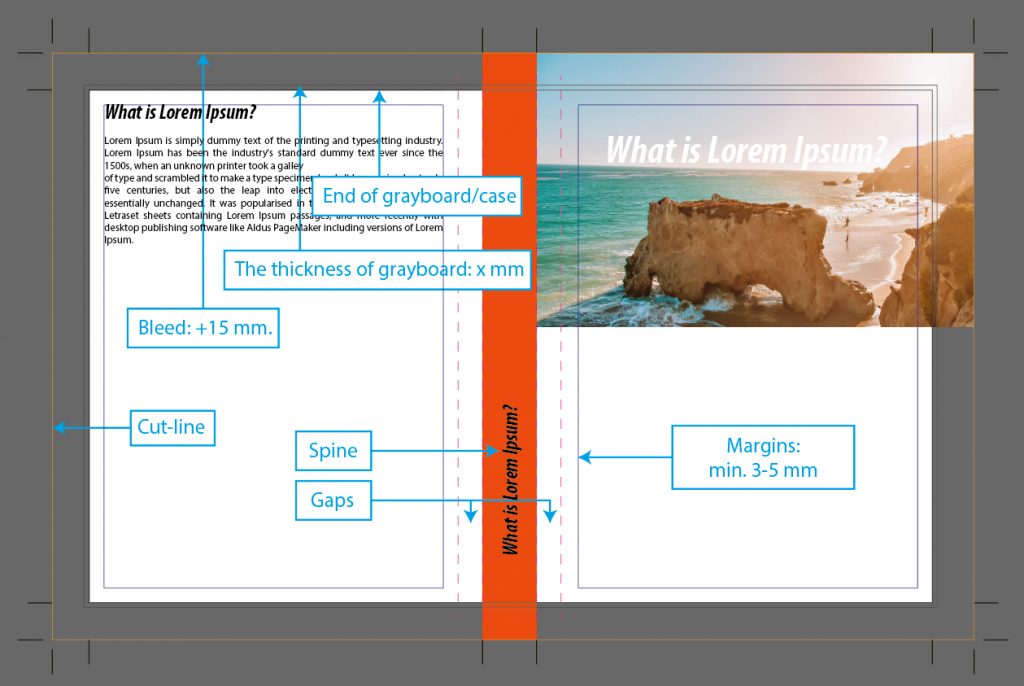

Hardback cover sizing

Please always consult our customer service for the exact sizing of the hardboard cover (ridge size, board size, plate thickness and punch size). This can be determined depending on the scope and material of the publication. If necessary, it is possible to make an unprinted prototype. The required bleed from the edge of the gray plate is the plate thickness + 15 mm. In order to ensure trouble-free production, it is necessary to keep a distance of 3-5 mm from the edge of the gray plates (for texts, logos, etc.), and the punch line must also be included in the graphic design of the cover. Outside the bleed, cut marks must be placed on the edges of the plates. These will serve as registration marks when laminating.

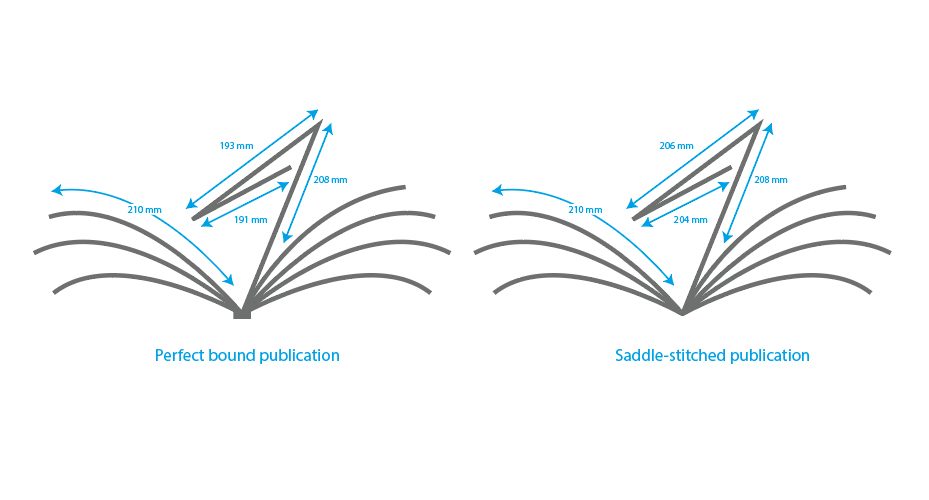

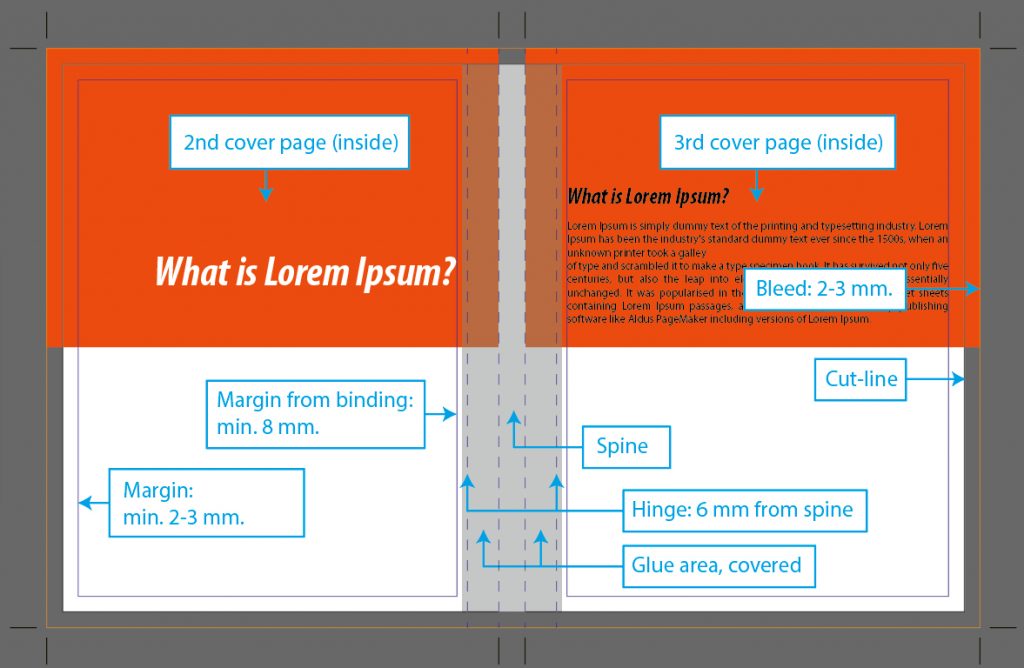

Glue-bound publications

In the case of glue-bound publications, the inside of the cover and the first and last pages of the inside are glued together and covered in a 6 mm strip along the opening strip. This means that these pages should be designed so that there can be no text or other content-sensitive graphics in a band of 8 mm from the edge of the binding side because they will not be visible.

Care should be taken when designing flowing text for readability. The adhesive part and side deflections must always be taken into account. Try to leave spaces in the binding and use the largest possible font size to get the right text image.

One color mutacion

For single-color varying publications (e.g., linguistic variation), black is usually the variable. When designing, make sure that all variable black text and graphic elements are set to overprint. Please submit the variations? in a separate PDF. Each must contain all the colors. Non-varying graphics should be the same in all versions. Separated PDF files are not accepted.

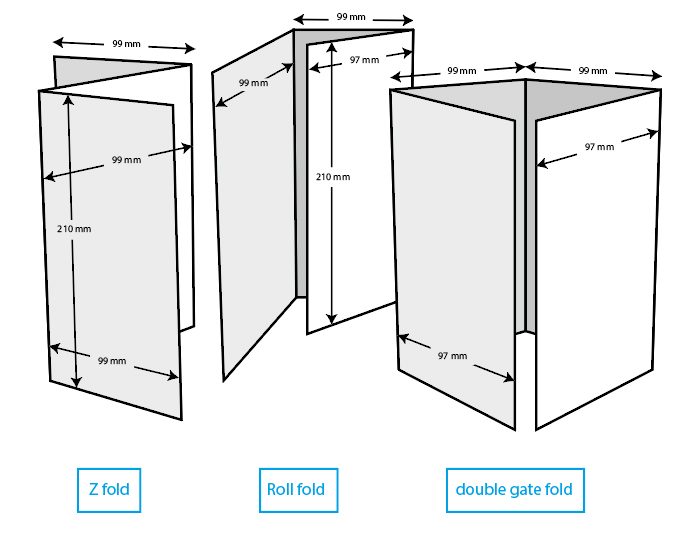

Folding and sizing of leaflets

In the case of leaflets, a distinction is made between Z, “rolled”? and “altar”? folding. For Z-fold, all sides must be the same size. In the case of “rolled”? and “altar”? folds, the width of the folded sides should be 2 mm smaller to avoid paper jams during folding. When designing your graphics, make sure that the size of the margins on these pages is also smaller.

Fold-out pages in the publication